ChemMax® 3

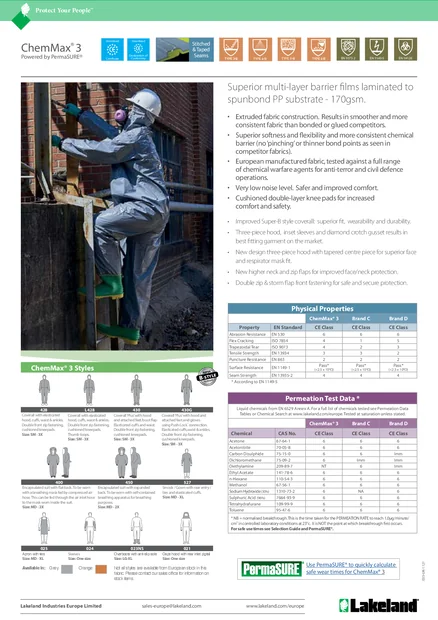

ChemMax® 3 provides a barrier against a broad spectrum of toxic industrial chemicals, dual-use chemicals, chemical warfare agents, and other harmful contaminants.

With a heat-sealed seam and a multi-layer film applied to the heavy polypropylene nonwoven fabric for increased strength and durability, ChemMax® 3 provides advanced chemical protection for industrial workers, emergency response teams, and law enforcement.

Safe-use times for ChemMax® 3 can be calculated using PermaSURE – a free, easy-to-use app that calculates safe-use times for over 4,000 chemicals. PermaSURE accounts for varying environmental conditions such as temperature, so you can make the most informed decision when protecting your people.

Products

Filter by Garment Type

More

Filter by Seam Type

More

ChemMax® 3 Chemical Test Data

| Chemical Tested | CAS Number | Phase | Concentration | ASTM F739 | EN 6529 | ISO Class | |

|---|---|---|---|---|---|---|---|

| 1,2-DICHLOROETHANE | 0107-06-02 | LIQUID | 99% | >480 | >480 | 6 | |

| 1,2-DICHLOROPROPANE | 78-87-5 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| 1,3-BUTADIENE GAS | 106-99-0 | LIQUID | 99% | >480 | >480 | 6 | |

| 1,4-DIOXANE | 123-91-1 | LIQUID | 99% | >480 | >480 | 6 | |

| 2,2,2-TRICHLOROETHANOL | 115-20-8 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| 2,4-DICHLOROPHENOL | 120-83-2 | LIQUID | 99% | >480 | >480 | 6 | |

| 2,4-DICHLOROPHENOXY ACETIC ACID | 94-75-7 | LIQUID | 99% | >480 | >480 | 6 | |

| 4,4-METHYLENEBIS | 5124-30-1 | LIQUID | 90% | NOT TESTED | NOT TESTED | ||

| ACETIC ACID | 64-19-7 | LIQUID | 99% | 95 | >480 | 6 | |

| ACETIC ANHYDRIDE | 108-24-7 | LIQUID | 99% | >480 | >480 | 6 | |

| ACETONE | 67-64-1 | LIQUID | 99% | >480 | >480 | 6 | |

| ACETONITRILE | 75-05-8 | LIQUID | 99% | 160 | >480 | 6 | |

| ACROLEIN | 0107-02-08 | LIQUID | 98% | >480 | >480 | 6 | |

| ACRYLIC ACID | 79-10-7 | LIQUID | 99% | 240 | >480 | 6 | |

| ACRYLONITRILE | 107-13-1 | LIQUID | 99% | 115 | >480 | 6 | |

| ALLYL ALCOHOL | 107-18-6 | LIQUID | 99% | >480 | >480 | 6 | |

| ALLYL CHLORIDE | 0107-05-01 | LIQUID | 98% | >480 | >480 | 6 | |

| AMMONIA | 7664-41-7 | GAS | 99% | >480 | >480 | 6 | |

| AMMONIUM HYDROXIDE | 1336-21-6 | LIQUID | 29% | 120 | 120 | 3 | |

| AMYL ACETATE | 628-63-7 | LIQUID | 99% | >480 | >480 | 6 | |

| ANILINE | 62-53-3 | LIQUID | 99% | >480 | >480 | 6 | |

| BENZENE | 71-43-2 | LIQUID | 99% | >480 | >480 | 6 | |

| BROMINE | 7726-95-6 | LIQUID | 99% | IMMEDIATE | IMMEDIATE | ||

| BUTYRALDEHYDE | 123-72-8 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| CARBON DISULFIDE | 75-15-0 | LIQUID | 99% | 178 | >480 | 6 | |

| CARBON MONOXIDE | 630-08-0 | GAS | 99% | IMMEDIATE | 320 | 5 | |

| CHLORINE | 7782-50-5 | GAS | 99% | >480 | >480 | 6 | |

| CHLOROACETIC ACID | 79-11-8 | LIQUID | 75% | NOT TESTED | NOT TESTED | ||

| CHLOROACETONE | 78-95-5 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| CHLOROBENZENE | 108-90-7 | LIQUID | 95% | 3 | 9 | ||

| CHLOROFORM | 67-66-3 | GAS | 99% | NOT TESTED | >480 | 6 | |

| CHLOROSULFONIC ACID | 7790-94-5 | LIQUID | 97% | NOT TESTED | NOT TESTED | ||

| o-Cresol | 95-48-7 | LIQUID | 99% | 25 | 33 | 2 | |

| CROTONALDEHYDE | 4170-30-3 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| CYCLOHEXANONE | 108-94-1 | LIQUID | 99% | >480 | >480 | 6 | |

| CYCLOHEXYL ISOCYANTE | 3173-53-3 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| DICHLORODIMETHYISILANE | 75-78-5 | LIQUID | 99% | >480 | >480 | 6 | |

| DICHLOROMETHANE | 75-09-2 | LIQUID | 99% | >480 | >480 | 6 | |

| DIESEL FUEL | MIXTURE | LIQUID | NEAT | >480 | >480 | 6 | |

| DIETHYL ETHER | 60-29-7 | LIQUID | 99% | >480 | >480 | 6 | |

| DIETHYLAMINE | 109-89-7 | LIQUID | 99% | 75 | 194 | 4 | |

| DIMETHYL SULFOXIDE | 67-68-5 | LIQUID | 99% | >480 | >480 | 6 | |

| DIMETHYLACETAMIDE | 127-19-5 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| DIMETHYLAMINE | 124-40-3 | LIQUID | 40% | NOT TESTED | NOT TESTED | ||

| DIMETHYLETHYLAMINE | 598-56-1 | LIQUID | 99% | 55 | 137 | 4 | |

| DIMETHYL FORMAMIDE | 68-12-2 | LIQUID | 99% | >480 | >480 | 6 | |

| DIMETHYLMALEATE | 624-48-6 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| EPICHLOROHYDRIN | 106-89-8 | LIQUID | 99% | 171 | 176 | 4 | |

| ETHANOL | 64-17-5 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| MONOETHANOLAMINE | 141-43-5 | LIQUID | 99% | >480 | >480 | 6 | |

| ETHYL ACETATE | 141-78-6 | LIQUID | 99% | >480 | >480 | 6 | |

| ETHYLBENZENE | 100-41-4 | LIQUID | 99% | >480 | >480 | 6 | |

| ETHYLENE DIBROMIDE | 106-93-4 | LIQUID | 99% | >480 | >480 | 6 | |

| ETHYLENE GLYCOL | 107-21-1 | LIQUID | 99% | >480 | >480 | 6 | |

| ETHYLENE OXIDE | 75-21-8 | GAS | 99% | >480 | >480 | 6 | |

| ETHYLENE OXIDE | 75-21-8 | GAS | 10% | >480 | >480 | 6 | |

| ETHYLENEDIAMINE | 107-15-3 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| FLUOBORIC ACID | 16872-11-0 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| FLUOROBENZENE | 0462-06-06 | LIQUID | 99% | >480 | >480 | 6 | |

| FLUOROSILICIC ACID | 16961-83-4 | LIQUID | 35% | NOT TESTED | NOT TESTED | ||

| FORMALDEHYDE | 50-00-0 | LIQUID | 37% | >480 | >480 | 6 | |

| FORMIC ACID | 64-18-6 | LIQUID | 95% | >480 | >480 | 6 | |

| GASOLINE | MIXTURE | LIQUID | NEAT | >480 | >480 | 6 | |

| GLUTARALDEHYDE | 111-30-8 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| HYDROCHLORIC ACID | 7647-01-0 | LIQUID | 37% | >480 | >480 | 6 | |

| HYDROFLUORIC ACID | 7664-39-3 | LIQUID | 48% | >480 | >480 | 6 | |

| HYDROFLUORIC ACID | 7664-39-3 | LIQUID | 50% | >480 | >480 | 6 | |

| HYDROGEN CHLORIDE | 7647-01-0 | GAS | 99% | >480 | >480 | 6 | |

| HYDROGEN FLUORIDE | 7664-39-3 | GAS | 99% | >480 | >480 | 6 | |

| HYDROGEN PEROXIDE | 7722-84-1 | LIQUID | 50% | >480 | >480 | 6 | |

| IODOMETHANE | 74-88-4 | LIQUID | 99% | >480 | >480 | 6 | |

| ISOAMYL ALCHOL | 123-51-3 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| ISOPROPANOL | 67-63-0 | LIQUID | 99% | >480 | >480 | 6 | |

| JET FUEL JP-8 | N/A | LIQUID | NEAT | >480 | >480 | 6 | |

| MERCURY II NITRATE | 7783-34-8 | LIQUID | PPM | NOT TESTED | |||

| METHANOL | 67-56-1 | LIQUID | 99% | 180 | >480 | 6 | |

| METHYL BROMIDE | 74-83-9 | LIQUID | 99% | >480 | >480 | 6 | |

| METHYL CHLORIDE | 74-87-3 | GAS | 99% | >480 | >480 | 6 | |

| METHYL ETHYL KETONE | 78-93-3 | LIQUID | 99% | >480 | >480 | 6 | |

| METHYL MERCAPTAN | 74-93-1 | LIQUID | 99% | >480 | >480 | 6 | |

| METHYL METHACRYLATE | 80-62-6 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| METHYLAMINE | 74-89-5 | LIQUID | 40% | 163 | >480 | 6 | |

| METHYLTHIOPROPIONALDEHYDE | 3268-49-3 | LIQUID | 99% | >480 | >480 | 6 | |

| MONOETHANOLAMINE | 141-43-5 | LIQUID | 99% | >480 | >480 | 6 | |

| o-Cresol | 95-48-7 | LIQUID | 97% | > 480 | > 480 | 6 | |

| BUTAN-1-OL | 71-36-3 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| Dibutyl ether | 142-96-1 | LIQUID | 99% | 58 | >480 | 6 | |

| HEPTANE | 142-82-5 | LIQUID | 99% | >480 | >480 | 6 | |

| HEXANE | 110-54-3 | LIQUID | 99% | >480 | >480 | 6 | |

| N-METHYL PYRROLIDONE | 872-50-4 | LIQUID | 99% | >480 | >480 | 6 | |

| NITRIC ACID | 7697-37-2 | LIQUID | 70% | >480 | >480 | 6 | |

| NITROBENZENE | 98-95-3 | LIQUID | 99% | 45 | 170 | 4 | |

| NITROGEN DIOXIDE | 10102-44-0 | LIQUID | 99% | >480 | >480 | 6 | |

| OLEUM | MIXTURE | LIQUID | NEAT | >480 | >480 | 6 | |

| P-XYLENE | 106-42-3 | LIQUID | 99% | >480 | >480 | 6 | |

| PCB (TRANSFORMER OIL) | PCB | LIQUID | Mixture | >480 | >480 | 6 | |

| PHENOL | 108-95-2 | LIQUID | 40% | >480 | >480 | 6 | |

| PHOSPHORIC ACID | 7664-38-2 | LIQUID | 85% | >480 | >480 | 6 | |

| PHOSPHORUS TRICHLORIDE | 7719-12-2 | LIQUID | 95% | IMMEDIATE | 20 | 1 | |

| POTASSIUM ACETATE | 0127-08-02 | LIQUID | SAT | NOT TESTED | NOT TESTED | ||

| POTASSIUM CHROMATE | 7789-00-6 | LIQUID | SAT | >480 | >480 | 6 | |

| POTASSIUM HYDROXIDE | 1310-58-3 | LIQUID | 88% | NOT TESTED | NOT TESTED | ||

| PROPYLAMINE | 0107-10-8 | LIQUID | 99% | IMMEDIATE | IMMEDIATE | ||

| PROPYLENE OXIDE | 75-56-9 | LIQUID | 99% | IMMEDIATE | >480 | 6 | |

| PYRIDINE | 110-86-1 | LIQUID | 99% | >480 | >480 | 6 | |

| SODIUM CARBONATE | 497-19-8 | LIQUID | 5% | >480 | >480 | 6 | |

| SODIUM CYANIDE | 143-33-9 | LIQUID | Saturated | >480 | >480 | 6 | |

| SODIUM HYDROXIDE | 1310-73-2 | LIQUID | 50% | >480 | >480 | 6 | |

| SODIUM HYPOCHLORITE | 7681-52-9 | LIQUID | 15% | >480 | >480 | 6 | |

| STYRENE | 100-42-5 | LIQUID | 98% | 342 | >480 | 6 | |

| SULPHUR DIOXIDE | 7446-09-05 | GAS | 99% | >480 | >480 | 6 | |

| SULFUR MONOCHLORIDE | 10025-67-9 | LIQUID | 99% | >480 | >480 | 6 | |

| SULFUR TRIOXIDE | 7446-11-9 | LIQUID | 99% | 50 | 80 | 3 | |

| SULFURIC ACID | 7664-93-9 | LIQUID | 97% | >480 | >480 | 6 | |

| SULFURIC ACID | 7664-93-9 | LIQUID | 30% | >480 | >480 | 6 | |

| SULFURIC ACID | 7664-93-9 | LIQUID | 98% | >480 | 6 | ||

| SULFURYL CHLORIDE | 7791-25-5 | LIQUID | 99% | 15 | 15 | 1 | |

| T-BUTYL METHYL ETHER | 1634-04-04 | LIQUID | 99% | >480 | >480 | 6 | |

| TETRACHLOROETHANE | 79-34-5 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| TETRACHLOROETHYLENE | 127-18-4 | LIQUID | 99% | >480 | >480 | 6 | |

| TETRAHYDROFURAN | 109-99-9 | LIQUID | 99% | 320 | >480 | 6 | |

| TETRAHYDROTHIOPHENE | 110-01-0 | LIQUID | 99% | IMMEDIATE | >480 | 6 | |

| THIONYL CHLORIDE | 7719-09-07 | LIQUID | 99% | IMMEDIATE | IMMEDIATE | ||

| TITANIUM TETACHLORIDE | 7550-45-0 | LIQUID | 99% | >480 | >480 | 6 | |

| TOLUENE | 108-88-3 | LIQUID | 99% | >480 | >480 | 6 | |

| TRICHLOROBENZENE | 87-61-6 | LIQUID | 99% | >480 | >480 | 6 | |

| TRICHLOROETHYLENE | 79-01-6 | LIQUID | 100% | IMMEDIATE | >480 | 6 | |

| TRICHLOROVINYLSILANE | 75-94-5 | LIQUID | 99% | NOT TESTED | NOT TESTED | ||

| TRIFLUOROACETIC ACID | 76-05-1 | LIQUID | 99% | >480 | >480 | 6 | |

| TURCO 5351 | MIXTURE | LIQUID | NEAT | >480 | >480 | 6 | |

| TURCO 6840 | MIXTURE | LIQUID | NEAT | >480 | >480 | 6 | |

| UNLEADED PETROL | MIXTURE | LIQUID | 99% | >480 | >480 | 6 | |

| VINYL ACETATE | 0108-05-04 | LIQUID | 95% | >480 | >480 | 6 | |

| VINYL CHLORIDE | 75-01-4 | GAS | 99% | >480 | >480 | 6 | |

| XYLENE | 1330-20-7 | LIQUID | 99% | 478 | >480 | 6 |

Please Note:

All test results quoted are from testing carried out at independent laboratories to the relevant {ASTM/CE} Standard(s). Unless stated otherwise tests are carried out on samples of the relevant protective material as opposed to finished garments. Note that all testing is conducted at specific temperatures according to ASTM or EN standard requirements. As permeation is affected by temperature it is important to consider the likely temperature in any application. Permeation test results record a time to a specific permeation rate as defined by the relevant standard and NOT a time to initial breakthrough of the chemical. Also note that differences may be apparent in some cases between CE and ASTM test results. Whilst the tests are similar, the CE standard records a time to a permeation rate of 1.0µg / min / cm2, whilst ASTM records a time to a permeation rate of 0.10µg / min / cm2. This may explain differences between results. As with all Personal Protective Equipment, selection should be based upon the end users risk assessment, it is the responsibility of the end user to determine the suitability of any PPE as part of this risk assessment and to comply with any/all legislative/governmental requirements. Contact Lakeland for more information.